Baker Perkins have been serving world bakery industry for long . It has installation across the globe and bakery equipments have been installed in numerous bakeries in world . Baker Perkins have been pioneer in bakery technologies its manufacturing expertise and services had made them world leader in bakery equipments .

Equipment manufacturing are categorised in following section in Baker Perkins

Bakery

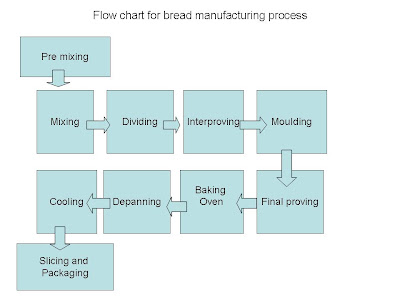

Baker Perkins' market leading mixing and forming equipment is based on over 100 years experience of the specialist needs of high-output plant bakeries producing a wide product range. Other areas of expertise include baking, and there is specialist equipment for the production of niche products such as pizza.

Biscuit , cookies , crackers and Pet food

Baker Perkins has the largest installed base, the widest range of equipment and the greatest depth of resources for the supply of processing machinery. From dough mixing to ovens that harness the latest scientific technologies, the Baker Perkins capability covers every conceivable type of product and added-value option. As well as offering 'best-in-class' equipment for each key process stage, there is constant development of new end products and processes.

Baker Perkins has the largest installed base, the widest range of equipment and the greatest depth of resources for the supply of processing machinery. From dough mixing to ovens that harness the latest scientific technologies, the Baker Perkins capability covers every conceivable type of product and added-value option. As well as offering 'best-in-class' equipment for each key process stage, there is constant development of new end products and processes.

Confectionery

Baker Perkins has almost a century of experience in the design, manufacture and commissioning of complete plants, with over 500 systems operational. They are used to make a wide selection, from hard candy, lollipops, butterscotch, milk boils and caramels to gum, fudge, fondant crèmes and jellies. Centre-fillings, multi-colours, stripes, layers, inclusions, sugar-free and sugar options are all available to bring variety and eye-catching appeal to the market place

Cereal and Snacks

Baker Perkins' world-class cereal cookers, twin-screw extruders, flaking rolls and toasters make the company the preferred partner for market-leading manufacturers of high-value cereal products. Every type of breakfast cereal is produced, as well as health/breakfast bars and cereal based baby foods. Baker Perkins also pioneered end product development and process technology to meet the expanding and rapidly changing needs of the snacks market, particularly in the field of twin-screw extrusion.

After Sales Service

Baker Perkins takes complete project from design to commissioning stage from customer . through their Aftermarket services from USA and UK based centres .Baker Perkins provides excellent support in terms of spares for their equipments such as moulds , dies , moulders and cutters , service contracts , benchmarking , optimising ,inspection and measuring equipments.

source : http://www.bakerperkinsgroup.com/

Perkins and Bakers were two most reputed brands for bakery equipments in 19th century England . Both companies were formed by two north Americans Jacob Perkins and Joseph Baker who emigrated to England for business . Both these companies then merged to form Baker Perkins in 1920 .

The business had expanded to become genuinely global in its organisation and sales when in 1987 the dairy and liquid food specialist, APV, acquired it. As APV Baker the company continued to develop its position at the forefront of the food sectors served. We can find many equipments with APV logo still working in bakeries .

In 2006 private investors John Cowx and Brian Taylor acquired Baker Perkins from APV and was renamed to original name of Baker Perkins .

HQ

UK

Peter borough

Baker Perkins Ltd.

Manor Drive,Paston Parkway,Peter borough

PE4 7AP

United Kingdom

Tel: +44 1733 283000,Fax: +44 1733 283001

Email :bpltd@bakerperkinsgroup.com

USA

Grand Rapids

Baker Perkins Inc.

3223 Kraft Ave. S.E.,Grand Rapids, MI,49512-2027

USA

Tel: +1 616 784 3111,Fax: +1 616 784 0973

Email: bpinc@bakerperkinsgroup.com

Website : http://www.bakerperkinsgroup.com/

.png)