Microbiological Hand Swab Reports For Your Workers

Food Handlers in bakeries are supposed to under go Hand swab test in regular intervals to ensure that the food which comes in contact with these workers are not contaminated with bacteria . This is also mandatory for food manufacturing units under ISO 22000 or HACCP certification .

This test also reflects the unit's hand washing , personeel hygiene training effectiveness . Most of the bakeries have hand washing dispenser installed at various exit and entry points as per their worker strength alongwith some anti bacterial soap solution and driers . Regular training are imparted to make worker learn the importance of hand washing in making bakery product contamination free . Swabs from machinery could also be sent alongwith these samples for the report .

They are several NABL approved labs which conducts these test and give reports against small fee. These swabs test sample are collected to determine the presence of microbes on food handler hands .

Microbes investigated are

ESCHERICHIA COLI Ref IS : 5887 ( part i 1976)

STAPHYLOCOCCUS SUREUS Ref IS : 5887 ( part ii )

SALMONELLA Ref IS : 5887 ( part iii )

CLOSTRIDIUM PERFRINGENS /BOTULINUM Ref IS : 5887 ( part iv )

VIBRIO CHOLERAE /PARAHAEMOLYTICUS Ref IS : 5887 ( part v )

B. CERUS - Ref IS : 5887 ( part vi )

Ref be made to BIS standards for minimum quantity permissible for bacteria mentioned above in hand swabs .Absence of these harmful bacterial would be the best results for the bakeries .

This test also reflects the unit's hand washing , personeel hygiene training effectiveness . Most of the bakeries have hand washing dispenser installed at various exit and entry points as per their worker strength alongwith some anti bacterial soap solution and driers . Regular training are imparted to make worker learn the importance of hand washing in making bakery product contamination free . Swabs from machinery could also be sent alongwith these samples for the report .

They are several NABL approved labs which conducts these test and give reports against small fee. These swabs test sample are collected to determine the presence of microbes on food handler hands .

Microbes investigated are

ESCHERICHIA COLI Ref IS : 5887 ( part i 1976)

STAPHYLOCOCCUS SUREUS Ref IS : 5887 ( part ii )

SALMONELLA Ref IS : 5887 ( part iii )

CLOSTRIDIUM PERFRINGENS /BOTULINUM Ref IS : 5887 ( part iv )

VIBRIO CHOLERAE /PARAHAEMOLYTICUS Ref IS : 5887 ( part v )

B. CERUS - Ref IS : 5887 ( part vi )

Ref be made to BIS standards for minimum quantity permissible for bacteria mentioned above in hand swabs .Absence of these harmful bacterial would be the best results for the bakeries .

Micro zap Technology To Increase The Shelf Life Of Bread

For long the researches and food technologist have been working for recipe , chemicals, packaging or technology to increase the shelf life of bread so that there could be control on food waste in which stale breads are major contributor

In normal condition the bread shelf in not more than 4-5 days for which the manufacturers have added preservatives and anti oxidant which definitely have some adverse impact on human body . The molds and fungus gets appearing from the 5th or 6 th day in storage thus making it stale .The packaging material which becomes moist while keeping the bread under wrap contributes to fungal growth . Food technologist have been trying to devise recipes or alternative packaging material which could kill these microbes for better shelf life thus reducing food waste in many countries .

To tackle this short shelf issue scientist s and researches at Micro zap have invented a new microwave technology to kill spores and molds for higher shelf which could be as long as 60 days .

A report

In normal conditions bread will go mouldy in around 10 days.

But an American company called Microzap says they have developed a technique that will keep the bread mould free for two months.At their laboratory on the campus of Texas Tech University in Lubbock, chief executive Don Stull showed off the long, metallic microwave device that resembles an industrial production line. Originally designed to kill bacteria such as MRSA and salmonella, the researchers discovered it could kill the mould spores in bread in around 10 seconds."We treated a slice of bread in the device, we then checked the mould that was in that bread over time against a control,” he explained."And at 60 days it had the same mould content as it had when it came out of the oven."

Micro zap rep also claims that this technology would not affect the taste ,texture and bread would be as fresh as it was on the day of production .The technology they are putting up is called cold pasteurization and as microwave employs pulsed power and multiple radio-frequency sources which will ensure energy is transmitted to the food in an even way.

source

thedailystar.net

visit microzap website :http://microzap.net

In normal condition the bread shelf in not more than 4-5 days for which the manufacturers have added preservatives and anti oxidant which definitely have some adverse impact on human body . The molds and fungus gets appearing from the 5th or 6 th day in storage thus making it stale .The packaging material which becomes moist while keeping the bread under wrap contributes to fungal growth . Food technologist have been trying to devise recipes or alternative packaging material which could kill these microbes for better shelf life thus reducing food waste in many countries .

To tackle this short shelf issue scientist s and researches at Micro zap have invented a new microwave technology to kill spores and molds for higher shelf which could be as long as 60 days .

A report

In normal conditions bread will go mouldy in around 10 days.

But an American company called Microzap says they have developed a technique that will keep the bread mould free for two months.At their laboratory on the campus of Texas Tech University in Lubbock, chief executive Don Stull showed off the long, metallic microwave device that resembles an industrial production line. Originally designed to kill bacteria such as MRSA and salmonella, the researchers discovered it could kill the mould spores in bread in around 10 seconds."We treated a slice of bread in the device, we then checked the mould that was in that bread over time against a control,” he explained."And at 60 days it had the same mould content as it had when it came out of the oven."

Micro zap rep also claims that this technology would not affect the taste ,texture and bread would be as fresh as it was on the day of production .The technology they are putting up is called cold pasteurization and as microwave employs pulsed power and multiple radio-frequency sources which will ensure energy is transmitted to the food in an even way.

source

thedailystar.net

visit microzap website :http://microzap.net

Britannia's Atta Bread

Britannia brings a new product to compete in healthy bread segment called " Atta" bread . Atta ( wheat flour ) is primary ingredients for ethnic breads for Indian house hold thus placing it into majority house hold grocery purchase .

Atta bread is slightly different with wheat flour content as it has more fibre % then Brown bread or whole wheat bread .Britannia Atta bread has 22% of whole wheat flour as declared in lable thus we can conclude that rest of flour 25-30% is wheat flour ( maida ) as ingredient .

Competition for Brown and Atta breads comes f rom formidable presence of local brands such as Mrs Bector s English oven , Harvest Gold and Bonn Bread

Atta bread is slightly different with wheat flour content as it has more fibre % then Brown bread or whole wheat bread .Britannia Atta bread has 22% of whole wheat flour as declared in lable thus we can conclude that rest of flour 25-30% is wheat flour ( maida ) as ingredient .

Competition for Brown and Atta breads comes f rom formidable presence of local brands such as Mrs Bector s English oven , Harvest Gold and Bonn Bread

Bakery Industry Representation In International Trade Fair 2012 , Delhi

This year International trade fair exhibition 2012 Delhi has fair representation from bakery industry . One of the largest trade promotion in India with domestic partner participation can be good platform for any exhibitor to show case to million of people .

I had opportunity for have brief visit to various halls to check products and manufacturers in Bakery Industry

Participants in Food segments were popular among general public as manufacturers were offering discounts , free trials ( taste ) , free goodies to the visitors .Britannia Industries Ltd -one of the largest manufacturer of bakery products was the surprise participant in this section as they are not regular participant in this exhibition.

| ||||||||

| courtesy - IITF.com |

Bakery Product Manufacturers

Britannia Industries Ltd - Biscuits , Cakes , Bread ,Rusk , Dairy Products

Bonn - Biscuits , Breads , Cakes , Rusk

Impressed with the fact that they had made a mark with large presentation of their products with various product s . Major attractions was of course bread segment with Jumbo Sliced Bread Pack .

Anmol - Biscuits

Dr Oetker - Sandwich Spreads

Bakery Equipment Manufacturer

Pritul Machine - Bakery Ovens , Bakery Mixers , Provers

Swift Pack - Packing machines , Shrink Wrap , Taping Machine

Millieum Packaging - Flow wrap machines

Britannia Diwali Gift Pack - Shubh Kamanayien

|

| Britannia Gift Packs For Festive Season |

Shubh Kamanayien Pack consists various biscuit pack such as Maska -Chaska , Goodday , Bourbon etc.

Glucose Biscuits Looses Out To Cream Biscuits & Cookies

There is a significant shift in consumer buying habits for biscuits in India . Marketing push for cream and cookies at low price tags have paid for , tier -2 cities and rural consumers have now shown interest in premium biscuit categories like cream and cookies .Parle -G remains the largest glucose brands but with low market share as compared to previous years .We can see the biscuit manufacturers coming out with numerous cream varieties. Britannia is aggressively marketing low cost Tiger cream brand .Glucose biscuit market share for entire biscuit segment is estimated to be 28% but is gradually losing out to premium cream and cookies biscuit .

We can place following cream biscuits brands in three level on price comparison

Top premium cream biscuits

Pure magic ( Britannia ) Dark Fantasy ( ITC ) Choco Kiss ( Unibic )

Middle level cream biscuits

Oreo ( Kraft ) , Orange cream ( Mcvities ) , Bourbon ( Britannia ) , Bourbon ( Parle & ITC )

Bottom level

Kremes ( Parle ) , Treats ( Britannia ) , Tiger creams ( Britannia ) , Creams (ITC ) , Creams ( Priya gold )

With small packs cream biscuits are now available for rural markets and people are buying out these in large number instead of popular biscuits such as glucose biscuits .

This sales fig are for months Apr -Sept sales ( Nielsen data ) shows the drop in glucose biscuit sale

Read more on this

ET

We can place following cream biscuits brands in three level on price comparison

Top premium cream biscuits

Pure magic ( Britannia ) Dark Fantasy ( ITC ) Choco Kiss ( Unibic )

Middle level cream biscuits

Oreo ( Kraft ) , Orange cream ( Mcvities ) , Bourbon ( Britannia ) , Bourbon ( Parle & ITC )

Bottom level

Kremes ( Parle ) , Treats ( Britannia ) , Tiger creams ( Britannia ) , Creams (ITC ) , Creams ( Priya gold )

With small packs cream biscuits are now available for rural markets and people are buying out these in large number instead of popular biscuits such as glucose biscuits .

This sales fig are for months Apr -Sept sales ( Nielsen data ) shows the drop in glucose biscuit sale

|

| source - ET |

Read more on this

ET

US Bakery Market Is Worth $ 30 Billion

US is the largest bakery product manufacturer in the world with China and India ranked 2nd & 3rd respectively .Bakery market revenue is estimated to $ 30 Billion per year .Average consumption of bakery products by Americans is about 25.4 kg per capita .

A report

The US bakery industry includes about 2,800 commercial bakeries with combined annual revenue of about $30 billion, along with about 6,000 retail bakeries with combined annual revenue of about $3 billion. Major companies include Hostess Brands, Flowers Foods, and Bimbo Bakeries USA (the US operations of Mexico's Grupo Bimbo). The commercial side of the industry is concentrated: the 50 largest companies generate 75 percent of revenue. The retail side of the industry is highly fragmented: the 50 largest companies generate about 15 percent of revenue, and the typical company operates just one facility.

Demand is driven by consumer preferences and by the extent to which grocery stores choose to operate their own bakeries rather than buy from commercial bakeries. Profitability for individual companies is determined by efficiency of operations. Large companies have scale advantages in procurement, production, and distribution. Small companies can compete by offering specialty goods or superior local distribution services. Retail bakeries are labor-intensive: average annual revenue per worker is about $45,000.

Major products include baked breads, mainly white, wheat and rye, which account for 40 percent of commercial bakery sales. About 20 percent of sales come from rolls, buns, muffins, bagels and croissants; 10 percent from soft cakes; and the rest from pies, pastries, donuts and a variety of sweet goods.

source - www.researchandmarkets.com

Baking Tip : Why Does Bread Collapse During Baking

Common problem during baking process in bread manufacturing is of collapsed bread during baking .This of course can be detected from fermentation and proving stages to do corrective measure the only disadvantage in bread production process is it cycle time which are as long as depending on the process adopted such as direct method chroleywood or sponge - method . It could vary from 4hrs - 2 hrs in for bread different styles of bread manufacturing .

Effect on bread

Remedies

Effect on bread

- Flattened( Collapsed) bread have large holes

- Collapsed bread texture

- Sour taste

- Use of weak flour could lead to weak texture which can not hold the

- Ambient temperature and quantity of yeast added

- Excess Fermentation - Qty of yeast or duration given for fermentation/Standing time

- Less salt or low salt during mixing process

- Deviation from standard mixing time /

- Improper water addition

- Over Proving

- High dough temperature check the temp of ingredient added plus ambient temperature higher the temperature higher would be the yeast activity which would over ferment the dough

- Excess humidity in prover .

Remedies

- Use strong flour - check parameter of flour before using it for production

- Reduce yeast quantity

- Reduce fermentation time

- Add salt of normal or standard quantity

- Reduce water quantity during mixing from earlier mixing

- Check proving time

- Reduce the dough temperature- check ingredient temperature . use chilled water if required .

- Reduce the final prover temperature - check the dough lift in the moulds to adjust the proving time

- Adjust the humidity

Britannia & Parle In Top 10 Most Trusted Brands

Economic Times have just released their list of most trusted brands of India . Good news is that Britannia ( ranked 2nd )and Parle ( Parle ranked 7th)both leading brands in baked products category are in top 10 .Which is significant for bakery industry although both are established brands with long history . They have beaten many mnc brands in getting consumer loyalties likes of Nokia ,Unilever ,P&G,Nestle, Pepsi , Coca Cola. Britannia have biscuits , cakes , bread , dairy and ready to eat products in its product mix where as Parle has biscuits , snacks and confectionery under its product portfolio .Britannia popular brands are Good Day , Marie Gold , Tiger , 5050 , Milk Bikis ,Bourbon & Nice .Similarly Parle has Parle -G , Krackjack ,Monaco , Happy Happy, Hide and Seek & Mango bite . Both Britannia and Parle have proved that with right talent and mentoring one can have brands which can take on Mnc's.

Top 10 Most trusted brand in India( fmcg ) are

1. Colgate

2. Britannia

3. Nokia

4. Clinic Plus

5. Dettol

6. Tata Salt

7. Parle

8. Mazza

9. Maggi

10.Lifebuoy

Other Food, Confectionery & Snacks Brands which have made the mark inTop 100 brands are

Tata Salt - 6

Maggi -9

Kukurkure - 36

Cadbury Milk Chocolate - 42

Sunfeast - 54

Nestle Milk Chocolate -62

Munch - 77

Kitkat - 80

Lays - 83

5 star - 94

Perk - 98

For complete list visit

Most Trusted Brands Of India - ET

Top 10 Most trusted brand in India( fmcg ) are

1. Colgate

2. Britannia

3. Nokia

4. Clinic Plus

5. Dettol

6. Tata Salt

7. Parle

8. Mazza

9. Maggi

10.Lifebuoy

Other Food, Confectionery & Snacks Brands which have made the mark inTop 100 brands are

Tata Salt - 6

Maggi -9

Kukurkure - 36

Cadbury Milk Chocolate - 42

Sunfeast - 54

Nestle Milk Chocolate -62

Munch - 77

Kitkat - 80

Lays - 83

5 star - 94

Perk - 98

For complete list visit

Most Trusted Brands Of India - ET

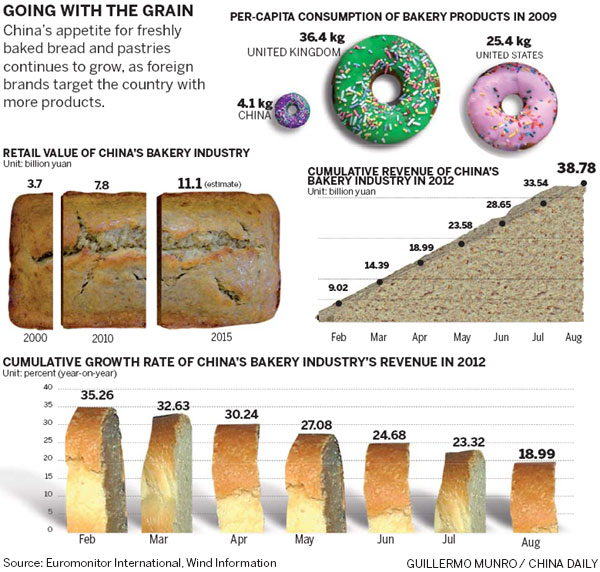

Bakery Trends In China

Chinese bakery industry is witnessing high growth alongwith its other industry . Rapid urbanization ,changing food habits and increase in middle class income are factors in making bakery products popular in China

Singapore bakery chain BreadTalk, for instance, said it has plans to increase its number of mainland outlets from 300 to 550 in the next couple of years.

Read more on chinadaily.com

Top 10 Chinese Biscuit Manufacturers

China is world second largest biscuit manufacturing country after United States . Few mncs have also entered chinese biscuit market but at large market is dominated by local brands .

Here are Top 10 biscuit manufacturer of China in terms of sales revenue and market share

Orion Food Co Ltd

Jinan Dali Food Co Ltd

PepsiCo Food (China) Co Ltd

Luohe Hengda Co Ltd

Oishi (China) Co Ltd

Anyang Jianfeng Food Co Ltd

Hubei Dali Food Co Ltd

Fujian Fuma Food Group Co Ltd

Fujian Dali Food Group Co Ltd

Chengdu Dali Food Co Ltd.

Source : Allchinareport.com

Here are Top 10 biscuit manufacturer of China in terms of sales revenue and market share

Orion Food Co Ltd

Jinan Dali Food Co Ltd

PepsiCo Food (China) Co Ltd

Luohe Hengda Co Ltd

Oishi (China) Co Ltd

Anyang Jianfeng Food Co Ltd

Hubei Dali Food Co Ltd

Fujian Fuma Food Group Co Ltd

Fujian Dali Food Group Co Ltd

Chengdu Dali Food Co Ltd.

Source : Allchinareport.com

Malpractices Prevalent In Bakeries

Bakeries adopts several malpractices in their greed to make quick money with utter disregard for consumer health or product quality . Few of them have made it a regular practice until caught whereas few of them take chances when they could pass on with minimum of risk .Lack of awareness of legal aspects and lower penalties encourage manufacturers to adopt malpractices in bakeries .

Consumers have to remain vigilant on this front as to report immediately to the concerned authorities if they find any thing missing either in taste or any health related issues after consuming these baked items .Following are signs for poor quality of baked items such as

Presence of foreign particles ( metal , sands , insects , threads , plastic , wrapper )

Pungent small

Fungus or bacterial growth

Poor packaging - seal broken or open packs

Misleading labels ( ingredients , allergens , date )

Poor taste

Stale items

Burnt small or taste

Less Weights

Adulteration by mixing low grade especially cheap and low nutrient material

Mixing inferior items with ingredients or diluting standard recipes for profit

Substitution of ingredients lesser known or inferior brand

Bakeries would buy inferior brands at very low cost to save money and make profits at the cost of consumers well being

Recycling of spoiled material

Many bakeries are found to recycle waste dough or rejected material to cut down waste thus lowering quality of product .

Unsanitary working condition

Manufacturers are found to neglect the sanitation and hygiene part of process to which cases of infestation and report of foreign particles in product are reported by consumers. Not having enough staff to do the cleaning of factory premises .

Lack of personal hygiene and sanitation

Lack of monitoring and neglecting personal hygiene aspects of food handler to save cost .

Use of fraudulent weights and measures

Giving less weight as declared on pack weight or playing with moisture content to have heavier product at the risk of product quality .

Not all bakeries adopt these malpractices but for few who indulge in these methods to make quick profit. Regulators and consumers should remain vigilant against such malpractices .

Consumers have to remain vigilant on this front as to report immediately to the concerned authorities if they find any thing missing either in taste or any health related issues after consuming these baked items .Following are signs for poor quality of baked items such as

Presence of foreign particles ( metal , sands , insects , threads , plastic , wrapper )

Pungent small

Fungus or bacterial growth

Poor packaging - seal broken or open packs

Misleading labels ( ingredients , allergens , date )

Poor taste

Stale items

Burnt small or taste

Less Weights

Adulteration by mixing low grade especially cheap and low nutrient material

Mixing inferior items with ingredients or diluting standard recipes for profit

Substitution of ingredients lesser known or inferior brand

Bakeries would buy inferior brands at very low cost to save money and make profits at the cost of consumers well being

Recycling of spoiled material

Many bakeries are found to recycle waste dough or rejected material to cut down waste thus lowering quality of product .

Unsanitary working condition

Manufacturers are found to neglect the sanitation and hygiene part of process to which cases of infestation and report of foreign particles in product are reported by consumers. Not having enough staff to do the cleaning of factory premises .

Lack of personal hygiene and sanitation

Lack of monitoring and neglecting personal hygiene aspects of food handler to save cost .

Use of fraudulent weights and measures

Giving less weight as declared on pack weight or playing with moisture content to have heavier product at the risk of product quality .

Not all bakeries adopt these malpractices but for few who indulge in these methods to make quick profit. Regulators and consumers should remain vigilant against such malpractices .

Star Bucks Opens Its First Store In Mumbai

With major business tv channels flashing the news of Starbuck opening its first store in Mumbai ,thus ending the gossip mills about the timing and the location for the Starbucks store . Starbucks chose the historic Elphinstone Building in the Horniman Circle neighborhood of south Mumbai.Capacity of this store would be of 120 guests .

Ceo and President of Starbucks Mr Howard Schultz alongwith Indian partner Tata ,s chairman Mr

Ratan Tata were present on this occassion .

Star Bucks being world number one in coffee chain across globe has been aggressive in promoting its business in Asia . It has around 700 outlets in mainland china where as in Japan its has more than 1000 outlets .

Pricing strategy would be important for Starbucks to take on the established players like Cafe Coffee Day ( CCD ) and Barista .

The trade mark bakery products for this stores would be sourced with in the local market .

More on this news

|

| Pic courtesy - India Today |

Ratan Tata were present on this occassion .

Star Bucks being world number one in coffee chain across globe has been aggressive in promoting its business in Asia . It has around 700 outlets in mainland china where as in Japan its has more than 1000 outlets .

Pricing strategy would be important for Starbucks to take on the established players like Cafe Coffee Day ( CCD ) and Barista .

The trade mark bakery products for this stores would be sourced with in the local market .

Tiffin Cakes From Britannnia

Tiffin cakes from Britannia Industries Ltd . Britannia which has almost complete dominance over branded bar cakes have now introduces block bar cake for kids . Winkies and few other players have already launched mini bar cakes in small packs . Britannia has now introduced this pack to take on competition head on .

The Bakemans Story

What went wrong for a very popular brand of north India " Bakemans " having wide range of products from biscuits , bread and cakes has been now sold to Srilankan company .

Excerpt For ET

In the 1990s, a north-based biscuits company, Bakemans Industries, gave industry leaders Britannia and Parle Products sleepless nights with its aggressively-priced offerings in the Marie and Glucose segments. The regional brand with an enviable 13% share, most of it coming out of Uttar Pradesh, was going places - until it decided to go national.

In the 1990s, a north-based biscuits company, Bakemans Industries, gave industry leaders Britannia and Parle Products sleepless nights with its aggressively-priced offerings in the Marie and Glucose segments. The regional brand with an enviable 13% share, most of it coming out of Uttar Pradesh, was going places - until it decided to go national.An attempt to carve out a pan-India presence ended in disaster with it plunging into a sea of red. To wipe out its losses, Bakemans raised prices on its home turf, in Uttar Pradesh. That move proved to be the proverbial final nail in the coffin; Bakemans not only failed to become a national player, it lost pole position in the market in which it once ruled the roost. The company was put up for sale, but even the acquisition by a Sri Lankan biscuit player ended calamitously.

The Bakemans debacle serves as a grim reminder for regional brands seeking to go national.

How Safe Is Your Bakery From Fire Hazard ?

In 20 years of baking career I had come across numerous fire incidents in bakery plants . Few were severe others were of smaller nature . These fire incidents raises doubt about the safety standards in the factory . Plant management has to convince people that things will not be repeated to erase fear from minds of workers .The damage caused and the production loss are heavy in such incidents . It takes numerous months to get the insurance claims from insurance companies . Any casualty in these incidents would have resulted in closure of plants , hence every precaution should be take to prevent or eliminate these fire incidents.

Plant were

Biscuit Plant

Fire in Ovens

Fire in bopp laminate waste in scrap yards

Bread Plant

Fire in ovens

You can see that majority of fire have taken in baking area ie is oven area , its natural that most risky place in the bakery production process is oven area with fuel like hsd , ldo , gas and rfo , even electric ovens are now being used in bakery process .

Following has contributed to fire in these cases

Biscuit

The hose pipe in burner came out from burner and fell on the hot plate of the burner zone thus inciting fire

Scrap yard caught fire as some one threw butt of cigarettes in that area .

Bread

In all the incidents , accumulation of bread,crumbs ,debris and remnant inside the the oven mostly in swing tray type oven has contributed for these fire incident .

Following precautions could have reduced and helped people to react to fire hazard in bakery .

- Get a insurance cover for accidents , fires for the factory

- Cleaning of oven periodically definitely would help .

- Have Emergency lights in different area

- Check all manual drives to take out things from oven

- Have Emergency number written in major production area

- Have mock drills in regular interval

- Check all fire safety equipments by third party

- Do the fire extinguishers refilling after the expired dates

- Designate some technical person as safety officer to concentrate on safety issues

- Get the NOC license from local bodies

- Training of workers for equipment used in process also helps in reduction of fire hazards

- Give safety ppe to workers in hot areas

- Use HOT working cards for jobs inside the

- Get fire hydrant installed for long term solution

- Have atleast UPS to drive the material out of ovens.

- Storage of Fuel and Gas to adhere to legal specification of the authorities .

- Install Fire extinguishers in plant

- Fire Hydrant Hose Pipes in several locations

- Install smoke and heat detectors in fire prone area .

Its only when such incident happens that the factory management looks into safety aspect . Simple lapses from factory management could result in heavy loss to the company.

1 Insurance Policy copy

2. Claim form

3. Fire brigade report

4. Police FIR

5. Witness statement ( any two ) first hand acct

6. Cause of accident in detail

7. Pics of the fire incident

8. List of damaged items

9. Log sheet of production report

10. Stock statement of the plant

11. Detail calculation of the loss

12 Raw mat cost supported by purchase invoices

13 Costing of WIP and FG

14. Destruction certificates for the burnt material

15 Balance sheet

16. Material to be kept till insurance company approves the damage and loss of material

So its better to have fire safety in place and avoid fire hazards in bakeries

Macadams International -World Major Bakery Equipment Manufacturer- A Profile

Macadams International is a major bakery equipment manufacturer from South Africa .It has strong presence in African continent and has establsihed a prominent place in other countries for retail bakery equipment segment .

Established in 1904 Macadams have been manufacturing bakery equipments , packing machines and bake ware. Macadams International is wholly owned subsdiary of Universal Industries . It is based at Capetown , Blackheath , South Africa .

Established in 1904 Macadams have been manufacturing bakery equipments , packing machines and bake ware. Macadams International is wholly owned subsdiary of Universal Industries . It is based at Capetown , Blackheath , South Africa .

Here are range of equipment manufactured by them

Baking Systems

Rack Ovens

Deck Ovens

Convection Ovens

Provers

Kneaders,Mixers,Bowl Hoists and Bulk Hoppers

Moulders

Dividers

Bread/Cake Slices

Pastry Sheeters

Industrial Frying Pan

Doughnut Fryer

Biscuit Machines

Water Chillers

Specialised Solutions

Food Service Solutions

Combi Oven

Chicken Grillers

Slicers

Foodwaste Disposers

Meal Merchandisers

Ice Cubers and Flakers

Fryers

Fridges,Freezers and Blast Chillers

Packaging

Dishwashers & Utensil Washers

Ovens

Premier Ranges

Oil Filtration Systems

Packaging Solutions

Macadams MacPak Automatic Packaging Machine

Macadams MacPak Horizontal Packaging Machine

Macadams MacPak Multiple Packaging Machine

HQ & Address

Established in 1904 Macadams have been manufacturing bakery equipments , packing machines and bake ware. Macadams International is wholly owned subsdiary of Universal Industries . It is based at Capetown , Blackheath , South Africa .

Established in 1904 Macadams have been manufacturing bakery equipments , packing machines and bake ware. Macadams International is wholly owned subsdiary of Universal Industries . It is based at Capetown , Blackheath , South Africa .Here are range of equipment manufactured by them

Baking Systems

Rack Ovens

Deck Ovens

Convection Ovens

Provers

Kneaders,Mixers,Bowl Hoists and Bulk Hoppers

Moulders

Dividers

Bread/Cake Slices

Pastry Sheeters

Industrial Frying Pan

Doughnut Fryer

Biscuit Machines

Water Chillers

Specialised Solutions

Food Service Solutions

Combi Oven

Chicken Grillers

Slicers

Foodwaste Disposers

Meal Merchandisers

Ice Cubers and Flakers

Fryers

Fridges,Freezers and Blast Chillers

Packaging

Dishwashers & Utensil Washers

Ovens

Premier Ranges

Oil Filtration Systems

Packaging Solutions

Macadams MacPak Automatic Packaging Machine

Macadams MacPak Horizontal Packaging Machine

Macadams MacPak Multiple Packaging Machine

HQ & Address

Head Office & Exports

Macadams Business Park

School Street

Blackheath

Cape Town

75811

Phone: +27 (0) 21 907-1000

Fax: +27 (0) 21 907-1111

Email: info@macadams.co.za

Macadams Business Park

School Street

Blackheath

Cape Town

75811

Phone: +27 (0) 21 907-1000

Fax: +27 (0) 21 907-1111

Email: info@macadams.co.za

Website : www.macadams.co.za

Top 5 Major Global Cereal Companies

Wheat or Corn Flakes with numerous flavors we love all of them be it local manufacturers brand or world major brands.

Here are the World Major Break fast cereal making companies with market share

Kelloggs - 32.1%

Corn Flakes , Crunchy Nuts , Frosted Flakes

General Mills - 10.6%

Cheerios , Trix and Lucky Charms

Cereal Partners World Wide - 9.8%

Nesquick , Fitness and Chocapic

Pepsico - 8.6%

Quaker s ,Puffed Wheat and Sugar Puffs

Ralcorp Holdings - 4.5 %

Private label brands

Source

Euromonitor

Here are the World Major Break fast cereal making companies with market share

Kelloggs - 32.1%

Corn Flakes , Crunchy Nuts , Frosted Flakes

General Mills - 10.6%

Cheerios , Trix and Lucky Charms

Cereal Partners World Wide - 9.8%

Nesquick , Fitness and Chocapic

Pepsico - 8.6%

Quaker s ,Puffed Wheat and Sugar Puffs

Ralcorp Holdings - 4.5 %

Private label brands

Source

Euromonitor

Mondelez International Comes Up With Oreo And Dairy Milk Chocolate Bar

Mondelez International newly spun company out of Kraft Food Inc has launched a new combination of two popular products Cadburys Dairy milk chocolate and Oreo cookies .It will be a milk chocolate bar containing a creamy filling with Oreo cookie pieces called Cadbury dairy milk with Oreo.

This new chocolate bar would be introduced in UK market from this week as per the news reports . Kraft food has been innovating products to increase its sales in competitive UK's biscuit market . Should be a winning combination for consumers .

Source

marketingmagazine.co.uk

This new chocolate bar would be introduced in UK market from this week as per the news reports . Kraft food has been innovating products to increase its sales in competitive UK's biscuit market . Should be a winning combination for consumers .

Source

marketingmagazine.co.uk

AIB To Open School On Baking In Greater Noida

Press Release by AIB .International school of Baking

AIB( American Institute of Baking) International School of Baking is committed to supporting the growth of the baking industry in the nation of India through professional training. By providing an opportunity for interested persons to learn the science and technology of baking, we hope to obtain a critical mass of proficiency that will allow bakery owners and managers to create new products, improve the quality of existing products, and assure that the bakeries are operating at lowest possible costs.

AIB( American Institute of Baking) International School of Baking is committed to supporting the growth of the baking industry in the nation of India through professional training. By providing an opportunity for interested persons to learn the science and technology of baking, we hope to obtain a critical mass of proficiency that will allow bakery owners and managers to create new products, improve the quality of existing products, and assure that the bakeries are operating at lowest possible costs.

This professional training will benefit the nation of India in the following ways:

- Increased variety of bakery products available- some more nutritious and others more indulgent

- Increased employment opportunities as the industry grows

- Control of pricing through reduction of costs rather than government regulation

The AIB International

School of Baking plans to pursue these goals through association

with Mr. Raj Kapoor, Chief Executive, Assocom-India Pvt. Ltd., Delhi,

India. Mr. Kapoor represents AIB International and the Department of

Grain Science and Industry at Kansas State University, both in

Manhattan, Kansas.

The

construction of the new Assocom Institute of Baking Technology &

Management in Greater Noida, Uttar Pradesh. would be completed by end of this year .

If you need any further details, please contact:

Raj Kapoor

Chief Executive

Assocom-India Pvt. Ltd.

Flat No. 601, DDA Building District Center

Plot No. 4, Laxmi Nagar, New Delhi - 110092

Tel. +91-11-47675218 (Direct) Cell: +91-9810158318,

Email: rajkapoor@vsnl.com, Skyp: kapoor.raj,

Mondelez A New Name For Cadbury India

Cadbury India would be now re -named as Mondelez as confirmed by news paper report . Cadbury India which has been taken over by Kraft Foods Inc in year 2010 has now been given new name as per Kraft food inc strategy to split it business into two new identity ie International business which includes Oreo , Nabisco other brands would be now under Mondelez International Brand where as North American local products retains Kraft Foods Group name.

As per the news report the brand cadbury would continue to be displayed with product with Mondelez replacing the manufacture name in labels .

As per the news report the brand cadbury would continue to be displayed with product with Mondelez replacing the manufacture name in labels . Indian subsdiary of Kraft Inc Cadbury are market leader in chocolate category and are now manufacturing OREO brand of biscuits under cadbury brand .Other products from Kraft Inc which are produced in India are Tang and Trident .

Source

ET

Parle Biscuits Nashik Plant Raided For Using Banned Ingredients

Its rare that we hear stories about food regulatory bodies acting against big names in food processing units for violation of Food Acts .Stringent action should be taken against such manufacturers for putting consumers health at risk .

Even as this news doesn't have any relation to bakery but for the fact that manufacturers are adulterating foods by adding banned ingredients . It is necessary to spread awareness among consumers to be alert on food safety matters .Food laws are meant to prevent manufacturers to play around with consumer health .

As reports have come from different news sources about recent raid in Parle Biscuits Pvt Ltd Nashik (Gondegaon) factory for using lactic acid in its confectionery product " Kaccha Mango Bite " . The raid was conducted after news of several kids being admitted for food poisoning after eating this candy broke out . Lactic acid has been banned to be used in confectionery items . Raid was conducted by officials of FDA .

Lactic acid and raw material have been seized and sent for analysis as reported .

Source

The Hindu

Indian express

Even as this news doesn't have any relation to bakery but for the fact that manufacturers are adulterating foods by adding banned ingredients . It is necessary to spread awareness among consumers to be alert on food safety matters .Food laws are meant to prevent manufacturers to play around with consumer health .

As reports have come from different news sources about recent raid in Parle Biscuits Pvt Ltd Nashik (Gondegaon) factory for using lactic acid in its confectionery product " Kaccha Mango Bite " . The raid was conducted after news of several kids being admitted for food poisoning after eating this candy broke out . Lactic acid has been banned to be used in confectionery items . Raid was conducted by officials of FDA .

Lactic acid and raw material have been seized and sent for analysis as reported .

Source

The Hindu

Indian express

Anmol To Launch Tejus Brand Of Biscuits

Anmol Bakers have launched a new brand of biscuit named "Tejus " in health segment of biscuit category . It has plan to bring digestive range of biscuit to cater demand from health conscious consumers looking out for diabetic and heart beneficial range of biscuits . Competition would come from all major biscuit manufacturers such as Britannia " Nutri choice " , United Biscuits " Mcvities " Digestive and others .

Anmol bakers have also declared their plans to enhance capacity in coming years through expansion of its Greater Noida plant .New green field projects in Odisha and Kolkata where it would have rusk unit along with biscuit line and cake plant .

All together investment in tune Rs 135.0 crores would be spent on these up coming projects . Anmol plans to increase it annual production capacity to 25000 ton per month from 16000 tons at present . Annual turnover of Anmol Bakers have been Rs 700 crore for this fiscal year .

Source

ET

Anmol bakers have also declared their plans to enhance capacity in coming years through expansion of its Greater Noida plant .New green field projects in Odisha and Kolkata where it would have rusk unit along with biscuit line and cake plant .

|

| courtesy : Anmol Bakers |

Source

ET

Popular Brands Of Bread In Australia

Bread are popular staple food in Australia and the trends is that people are moving away from white breads to other options such as pasta and ready to eat snacks .Other popular categories of bread are Fruit breads and Rolls/Buns in Australia . Australia's average consumption of bread is around 52 kg per capita from high of 63 kg per capita in earlier years .

Two major manufacturers of bread are

Goodman Fielder

Brands of Bread :

Country Life Bakery ,Flinders Bread,Freya's,Helga's,Helga's Seed Sensations,La Famiglia,Lawson's

Leaning Tower,MacKenzie,Mighty Soft,Molenberg,Nature's Fresh,Quality Bakers,Vogel's,Wonder White

George Weston Foods

Brands of Bread

Tip Top, Sunblest, 9 Grain, Noble Rise, UP, Burgen, Golden , Big Ben

Other popular bread brands in Australia are

Wool worth

Coles

Bakers Delight

Brumby's

Banjo's

|

| coutesy:goodman fielder |

Two major manufacturers of bread are

Goodman Fielder

Brands of Bread :

Country Life Bakery ,Flinders Bread,Freya's,Helga's,Helga's Seed Sensations,La Famiglia,Lawson's

Leaning Tower,MacKenzie,Mighty Soft,Molenberg,Nature's Fresh,Quality Bakers,Vogel's,Wonder White

|

| courtesy : George weston foods |

George Weston Foods

Brands of Bread

Tip Top, Sunblest, 9 Grain, Noble Rise, UP, Burgen, Golden , Big Ben

Other popular bread brands in Australia are

Wool worth

Coles

Bakers Delight

Brumby's

Banjo's

Branding Of Ethnic Food Product

As expected some enthusiast has started branding of ethnic products which are presently sold either by retailers , street hawkers or some specialty sweet shops.

Here is an example of our own 'Gud KiChikki" - (Peanut in bar of jaggery ) . Expect few more ! . Malls and super markets have started putting up these products on shelf thus catering to local taste and products which is good for manufacturers . Few examples are rusk , bhujia , ghujia , gazaks , chiwda , varth related snacks etc .

Here is an example of our own 'Gud KiChikki" - (Peanut in bar of jaggery ) . Expect few more ! . Malls and super markets have started putting up these products on shelf thus catering to local taste and products which is good for manufacturers . Few examples are rusk , bhujia , ghujia , gazaks , chiwda , varth related snacks etc .

10 words every baker should know

Bakers plays an important role in entire bakery process . The person on which entire product quality depends .The one who modify or changes parameters if something goes wrong he needs to fix the problem ,Thus for him following 10 parameters or bakery terms are critical

- Dough Temperature

- Gluten Percentage

- Dough Raising Capacity ( DRC )

- Mixing Time

- Fermentation Time

- Dividing Weight

- Proving Time

- Proving Temp

- Baking Time

- Baking Temperature

Tamper Proof Packaging For Bread

Major bread manufacturer s in India have now opted for tamper proof packaging as popular method of bread packaging . Its interesting to know the fact that this kind of packaging was attempted is early 90's but with little success . Now this kind of packaging has been promoted by bread manufacturers with large retail shops opening up in India like Big bazar , Food bazar , Easy Day , Spencers and many more . Britannia , Harvest Gold , Bonn and Cremica are few major bread manufacturers using these types of tamper proof carry bags .It consists of adhesive tape with or without paper tag.

List Of Wheat Flour Mills In India

Bakeries normally source their flour requirement from local flour millers . Every state has their own local flour millers yet few of the flour brands or mills have grown up in size and operations and are supplying flours across countries . Punjab and Haryana are two major wheat producing states thus having large flour mills in comparison rest of the country . Flour are categorised as bread flour or biscuit flour as per the requirement of bakeries . Some times premium flour varieties for cake and pastries .

Here are few major flour suppliers to bakeries

Rajdhani Flour Mills Ltd

Cargill Foods

Shakti Bhog

Modern Flour Mills Ltd

BTS Flour Mill

Ahaar International

Amar Flour Mills

Delhi Flour Mill Ltd

Sree Vengopal Flour Mills

Shiv Roller Flour Mills

Modi Flour Mills

Rajdhani Roller Flour Mills (p) Ltd

Arti Food and Fats (P) Ltd

Bambino Argo Ind. Ltd

Panchkula Roller Flour Mills (P) Ltd.

Victoria Foods Private Limited

Here are few major flour suppliers to bakeries

Rajdhani Flour Mills Ltd

Cargill Foods

Shakti Bhog

Modern Flour Mills Ltd

BTS Flour Mill

Ahaar International

Amar Flour Mills

Delhi Flour Mill Ltd

Sree Vengopal Flour Mills

Shiv Roller Flour Mills

Modi Flour Mills

Rajdhani Roller Flour Mills (p) Ltd

Arti Food and Fats (P) Ltd

Bambino Argo Ind. Ltd

Panchkula Roller Flour Mills (P) Ltd.

Victoria Foods Private Limited

Bhawani Roller Flour Mills Ltd

Shree Ram Flour Mill

We can get exhaustive list of flour millers on

WhenYour Food Packaging Goes Wrong Or Is this Convenience Packaging ?

Watch this funny video highlighting problems with packaged food products. After its all about convenience packaging

Baker's Yeast Specification & Standards For Bakeries

Yeast is a vital ingredient in bakery process and should have following specifications as per standards of bakery manufacturer and products . Quality of yeast determines the end product .

Standards for Baker yeast

Bakers Yeast : Saccharomyces

Percentage Moisture

Dispersibility

Fermenting Power

Dough Raising Capacity or DRC ( Most critical )

Proteolytic activity

Heavy metals and alfatoxins

Microbiology Aspects

Bacteria microflora other than yeasts/gm

E.coli / gm

Salmonella/gm

Coliform Count/gm

Rope spore count /g

Storage Conditions - 4-7deg c

Storage Time - Not more than 15 days

Standards for Baker yeast

Bakers Yeast : Saccharomyces

Percentage Moisture

Dispersibility

Fermenting Power

Dough Raising Capacity or DRC ( Most critical )

Proteolytic activity

Heavy metals and alfatoxins

Microbiology Aspects

Bacteria microflora other than yeasts/gm

E.coli / gm

Salmonella/gm

Coliform Count/gm

Rope spore count /g

Storage Conditions - 4-7deg c

Storage Time - Not more than 15 days

Why Water Is Critical For Bakery Operations

Water apart from being an important ingredient in all bakery recipe has other functions in bakery to perform in bakery units

Role of water as ingredient

Helps in developing gluten in mixing

Forms emulsion alongwith fat

Forming Solutions for better mixing

Give moisture to end product for better taste

Helps in fermentation

Type of water

Hard

Soft

Alkaline

Source

Treated water from Municipality

Under ground water from bore well

Quantity and Quality of water are critical for better end product . Quantity of water are impacted by quality of flour and other ingredients where as quality can be checked through lab analysis of water characterisitics and adhering of standard water quality prescribed by authorities such as hardness , microbiological counts and heavy metal presence .

For potable water in bakery .Reference has to be BIS standard

Other Usage Of Water In Bakeries

Temperature control

Water is circulated in mixer jackets or added to control dough temperatures

Steam is generated to provide temp and humidity during proving which increases or decreases fermentation time .

Cleaning

Used in large quantity to clean floors and utensils in bakeries . CIP are done for liquid handling systems .Plastic trays and pallets are washed and cleaned by water .

Utility functions

Boiler

Hot water generators

Chilling Plants

Cooling towers

Water treating plants

To get water of desired properties bakeries do install water treatment plant such as RO systems . Filters can be used at end use of water in process to prevent contamination.

Role of water as ingredient

Helps in developing gluten in mixing

Forms emulsion alongwith fat

Forming Solutions for better mixing

Give moisture to end product for better taste

Helps in fermentation

Type of water

Hard

Soft

Alkaline

Source

Treated water from Municipality

Under ground water from bore well

Quantity and Quality of water are critical for better end product . Quantity of water are impacted by quality of flour and other ingredients where as quality can be checked through lab analysis of water characterisitics and adhering of standard water quality prescribed by authorities such as hardness , microbiological counts and heavy metal presence .

For potable water in bakery .Reference has to be BIS standard

Other Usage Of Water In Bakeries

Temperature control

Water is circulated in mixer jackets or added to control dough temperatures

Steam is generated to provide temp and humidity during proving which increases or decreases fermentation time .

Cleaning

Used in large quantity to clean floors and utensils in bakeries . CIP are done for liquid handling systems .Plastic trays and pallets are washed and cleaned by water .

Utility functions

Boiler

Hot water generators

Chilling Plants

Cooling towers

Water treating plants

To get water of desired properties bakeries do install water treatment plant such as RO systems . Filters can be used at end use of water in process to prevent contamination.

Does Your Bakery Have Food Safety Measures ?

Food safety needs to be the top priority for any bakery business owner . Here are following food safety measures for small to large bakeries .

Visitor Policy

Jewellery Policy

Plastic Policy

Glass Policy

Personal Hygiene Checks

Pest Control Management

Uniform Management

Sanitation Management

Building Maintenance

Food safety management system

Food safety Audit s

Storage system for raw material

Proper Drainage system

Maintenance system -Lubrication

Material Construction of equipments

Water Management

Solid Waste management

Training for work force

Equipments like - Air curtains/ Pvc strips/ Insect Killers/ Pallets /Rodent Boxes

Metal Detection systems

Filters / Sieves

Hazard Analysis done for HACCP

CCP's( Critical Control Points ) Identified

PRP ( Pre -requisite programs ) and OPRP ( Operational Pre requisite programs ) monitored ,updated

Visitor Policy

Jewellery Policy

Plastic Policy

Glass Policy

Personal Hygiene Checks

Pest Control Management

Uniform Management

Sanitation Management

Building Maintenance

Food safety management system

Food safety Audit s

Storage system for raw material

Proper Drainage system

Maintenance system -Lubrication

Material Construction of equipments

Water Management

Solid Waste management

Training for work force

Equipments like - Air curtains/ Pvc strips/ Insect Killers/ Pallets /Rodent Boxes

Metal Detection systems

Filters / Sieves

Hazard Analysis done for HACCP

CCP's( Critical Control Points ) Identified

PRP ( Pre -requisite programs ) and OPRP ( Operational Pre requisite programs ) monitored ,updated

PPE''s

Types Of Dough Tipping Device

Several types of Dough Tilters or Dough Tipping device can be used for dough feeding systems in bakeries . Dough tilting is required to transfer dough from Dough bowl after mixing to next stage , it could be Diving for Bread or Laminating for biscuits or Depositors in cookies production .Major mechanism for dough tilters is either hydraulic , screw and chain type.

Following Different Types Dough Tilters

Combination of mixer alongwith Dough Tilter

Inclined chain types dough tilters

Straight Lead Screw types tilters

Inclinded Lead Screw type tilters

Moving type -on the wheel dough tilters

Following Different Types Dough Tilters

Combination of mixer alongwith Dough Tilter

Inclined chain types dough tilters

Straight Lead Screw types tilters

Inclinded Lead Screw type tilters

Moving type -on the wheel dough tilters

Pest Birds Control In Bakeries

Some times bakeries have to face problem from birds entering into production hall . Pest bird control measures becomes important to prevent such occurence . Bakeries being food factory are attraction for these birds as they have different kinds of food available for them .

Bird can enters production hall through entrances , roof , damaged windows and gaps or holes in the wall s. . Normally birds which can be seen are crows , pigeon , doves,sparrows ,maina and even bats in some cases .

Chances of bird feces , feathers and debris contaminating the products are very high if these birds are not stopped from frequenting the production area .It has been observed that the feces could even damage the exterior paints of wall with their stains . Huge cost are incurred while doing re -painting in such area s . Arches and chajja s are best places for birds to build their nest s.

Here are few Pest Bird control measures

Bird Netting

Nets could be placed under the trusses of building to avoid birds resting places .

Bird s glue

Audio and lights

Bird Spikes

Spikes are placed on area frequented by the birds so as to prevent them from landing and then entering into bakery production halls

Bird mist

Mist of certain chemicals prevent these birds to come inside the production hall.

other articles

Pest control in bakeries

Bird can enters production hall through entrances , roof , damaged windows and gaps or holes in the wall s. . Normally birds which can be seen are crows , pigeon , doves,sparrows ,maina and even bats in some cases .

Chances of bird feces , feathers and debris contaminating the products are very high if these birds are not stopped from frequenting the production area .It has been observed that the feces could even damage the exterior paints of wall with their stains . Huge cost are incurred while doing re -painting in such area s . Arches and chajja s are best places for birds to build their nest s.

Here are few Pest Bird control measures

Bird Netting

Nets could be placed under the trusses of building to avoid birds resting places .

Bird s glue

Audio and lights

Bird Spikes

Spikes are placed on area frequented by the birds so as to prevent them from landing and then entering into bakery production halls

Bird mist

Mist of certain chemicals prevent these birds to come inside the production hall.

other articles

Pest control in bakeries

Why Cheap Labor Is Not Cheap For Bakeries

What drive these big companies in bakery industry for contract manufacturing and co -packer arrangement is low cost labor and cheap labor . The Co-packers ( CP ) or CMU ( Contract manufacturing units ) employs several contractors to get workers at very low salaries mostly unskilled and with low literacy rates . As workers are not aware of the legal wages these small companies make huge money out of these worker .

This is how companies cut over head cost of workers in these units as they don't pay for

No ESI ( Employee contribution from contractors or companies

No PF ( Provident Fund )deduction and contribution from the contractors or companies

No Gratuity for the workers who worked for more than five years

No Earned Leave for these workers

No Standard Over time payment

No Incentives or Bonus linked with production

No Medical or Insurance for the worker

No Uniform and Clothing Allowances .

Deduction in salaries for flimsy ground or absence

( Will State agencies look into these malpractices which are rampant in such units some of which mandatory by law payable to the workers ? )

As these workers are paid less there fore the rate of attrition is very high thus impacting the product quality and the process . Also as these workers starts searching for better opportunities or work part time doing extra jobs, which negates what ever efforts these companies have put to train them thus entering into vicious cycle of training unskilled labour all the time

Cheap labor has its own cost which companies are aware of but for profits they try to run the production with these workers .

Here are few negative results from cheap labor

Production inefficiency

High Maintenance cost due to break downs

High number of foriegn body complaints

High cost on continuous training ( few opts for no training )

More Product recalls

More consumer complaints due to defective s

Stress on supervisory personnel .

Major Accidents & Cuts

Hence it can be concluded that cheap labor is actually costlier than skilled and qualified labor . Companies should recognize this and aim for building effective and productive labor in longer run

This is how companies cut over head cost of workers in these units as they don't pay for

No ESI ( Employee contribution from contractors or companies

No PF ( Provident Fund )deduction and contribution from the contractors or companies

No Gratuity for the workers who worked for more than five years

No Earned Leave for these workers

No Standard Over time payment

No Incentives or Bonus linked with production

No Medical or Insurance for the worker

No Uniform and Clothing Allowances .

Deduction in salaries for flimsy ground or absence

( Will State agencies look into these malpractices which are rampant in such units some of which mandatory by law payable to the workers ? )

As these workers are paid less there fore the rate of attrition is very high thus impacting the product quality and the process . Also as these workers starts searching for better opportunities or work part time doing extra jobs, which negates what ever efforts these companies have put to train them thus entering into vicious cycle of training unskilled labour all the time

Cheap labor has its own cost which companies are aware of but for profits they try to run the production with these workers .

Here are few negative results from cheap labor

Production inefficiency

High Maintenance cost due to break downs

High number of foriegn body complaints

High cost on continuous training ( few opts for no training )

More Product recalls

More consumer complaints due to defective s

Stress on supervisory personnel .

Major Accidents & Cuts

Hence it can be concluded that cheap labor is actually costlier than skilled and qualified labor . Companies should recognize this and aim for building effective and productive labor in longer run

Basic Building Guidelines For Bakery Factory

When planning a layout for bakery unit or factory following building or construction guidelines to be kept in consideration

1. Adequate space for the machinery and equipments

2. Adequate Height in production hall

3.Ventilation arrangement such as windows and roof

4. Roofing Material - Metallic Sheet

5. Flooring material

6. Adequate Storage Area - Space for transport to unlaod

7.Adequate Dispatch Area - Space for transport

8 20 feet road around the premise for emergency services

9 Wash Rooms and Change rooms

10 Cold Storage Rooms

12 Waste Disposal Area

13 Fuel Storage Area

14 Drainage and water treatment plant

15 Fire hydrant system

16 Earth Quake and All weather walls

17 Passages , , Staircase Entrance and Exits

18 Mezzanine and Basements

19 Provision for further expansion

20 Air lines and water pipelines and support

21 Electrical cables and support

22 Utility area and its proximity to plant

23 Lighting Fixtures

1. Adequate space for the machinery and equipments

2. Adequate Height in production hall

3.Ventilation arrangement such as windows and roof

4. Roofing Material - Metallic Sheet

5. Flooring material

6. Adequate Storage Area - Space for transport to unlaod

7.Adequate Dispatch Area - Space for transport

8 20 feet road around the premise for emergency services

9 Wash Rooms and Change rooms

10 Cold Storage Rooms

12 Waste Disposal Area

13 Fuel Storage Area

14 Drainage and water treatment plant

15 Fire hydrant system

16 Earth Quake and All weather walls

17 Passages , , Staircase Entrance and Exits

18 Mezzanine and Basements

19 Provision for further expansion

20 Air lines and water pipelines and support

21 Electrical cables and support

22 Utility area and its proximity to plant

23 Lighting Fixtures

Industrial Mezzanine Floors - Storage Solution For Bakeries

While planning layout for bakery plant one can save space or eliminate need of additional floors through mezzanine floors in new project or in the existing set ups . Additional space can be generated in bakery production hall through fabricated mezzanine floors . Normally they are installed and fabricated in end of the production hall with access to it through staircase . It utilises empty over head space in bakery plants. Industrial mezzanine floors could be planned for

Storage of raw material

Storage of packing material

Storage of finished material

Setup Pre mixing Area for ease of feeding

Offices in bakery plant

Other material handling equipments would be require for heavy loads such as

Elevators

Fork lift s

Industrial mezzanine could cover entire production hall span or could be made for a section of the entire span .Mainly steel structures are used as frames with reinforcement made through steel beams and channel sections . Selection of these structures could be done by calculating load of items to be kept on these mezzanine .Columns are provided if the span is very large to support the structure . Handrails are provided for extra safety for safe working on these mezzanine . Pre fabricated racks and shelves could be used for storage purpose .Other material which can be used are aluminium and fibre glass.Other advantage of these Industrial Mezzanine is that it can easily dismantled or relocated to other location .

Flooring s could be of steel sheets , chequer plate or chip boards . False ceilings can used to cover the structure from under neath .

Most of the biscuit and bread factories have these Industrial mezzanine floors in one or other forms . As we need to provide enough height for production hall for better ventilation and heat dissipation .

Storage solutions - Racking

Bulk handling System

Storage of raw material

Storage of packing material

Storage of finished material

Setup Pre mixing Area for ease of feeding

Offices in bakery plant

Other material handling equipments would be require for heavy loads such as

Elevators

Fork lift s

|

| courtesy:indiamart.com |

Flooring s could be of steel sheets , chequer plate or chip boards . False ceilings can used to cover the structure from under neath .

Most of the biscuit and bread factories have these Industrial mezzanine floors in one or other forms . As we need to provide enough height for production hall for better ventilation and heat dissipation .

Storage solutions - Racking

Bulk handling System

How Cassava Flour Helps Nigeria To Reduce Wheat Flour Import

Cassava Flour usage in bread and other bakery products have been encouraged by the local government of Nigeria .Recently a bill would be introduced into national assembly to make cassava flour induction mandatory for bread manufacturers .

Cassava plants are of two varieties -sweet and bitter varieties . Cassava flour is being used by local population to prepare their staple food .Nigeria is the largest cassava flour producer in the world.

At one side Nigerian government is promoting local flour and has increased duties on imported wheat ( levies upto 20 % )/Wheat flour( duties upto 100 % ) which would hurt the local bakeries dependent on wheat flour as prices of bakery products such as bread ,pastries and noodles would be impacted most due to high prices . HQCF ( High quality cassava flour) has been developed by IITA ( International Institute of Tropical Agriculture) . IITA claims to substitute wheat flour by 40 % of cassava flour in bread without affecting bread characteristics .

At one side Nigerian government is promoting local flour and has increased duties on imported wheat ( levies upto 20 % )/Wheat flour( duties upto 100 % ) which would hurt the local bakeries dependent on wheat flour as prices of bakery products such as bread ,pastries and noodles would be impacted most due to high prices . HQCF ( High quality cassava flour) has been developed by IITA ( International Institute of Tropical Agriculture) . IITA claims to substitute wheat flour by 40 % of cassava flour in bread without affecting bread characteristics .

A balanced approach could save wheat flour millers and bakers which are dependent on wheat for their jobs where as cassava promotion can provide jobs to million cassava planters with saving in imports cost .Value of wheat imports per year in Nigeria is $ 252 Mn .

Cassava flours is extracted from tubers/ roots of cassava plant . The processing includes peeling/washing, drying , pulverizing and Milling .

Similar exercise has been adopted by Srilankan government by promoting Rice flour for bakery products with high import duties on wheat .

There is nothing wrong in substitution but the problem is on the ban of wheat .Let the common man in these country decide what he likes to eat .

Cassava plants are of two varieties -sweet and bitter varieties . Cassava flour is being used by local population to prepare their staple food .Nigeria is the largest cassava flour producer in the world.

At one side Nigerian government is promoting local flour and has increased duties on imported wheat ( levies upto 20 % )/Wheat flour( duties upto 100 % ) which would hurt the local bakeries dependent on wheat flour as prices of bakery products such as bread ,pastries and noodles would be impacted most due to high prices . HQCF ( High quality cassava flour) has been developed by IITA ( International Institute of Tropical Agriculture) . IITA claims to substitute wheat flour by 40 % of cassava flour in bread without affecting bread characteristics .

At one side Nigerian government is promoting local flour and has increased duties on imported wheat ( levies upto 20 % )/Wheat flour( duties upto 100 % ) which would hurt the local bakeries dependent on wheat flour as prices of bakery products such as bread ,pastries and noodles would be impacted most due to high prices . HQCF ( High quality cassava flour) has been developed by IITA ( International Institute of Tropical Agriculture) . IITA claims to substitute wheat flour by 40 % of cassava flour in bread without affecting bread characteristics .A balanced approach could save wheat flour millers and bakers which are dependent on wheat for their jobs where as cassava promotion can provide jobs to million cassava planters with saving in imports cost .Value of wheat imports per year in Nigeria is $ 252 Mn .

Cassava flours is extracted from tubers/ roots of cassava plant . The processing includes peeling/washing, drying , pulverizing and Milling .

Similar exercise has been adopted by Srilankan government by promoting Rice flour for bakery products with high import duties on wheat .

There is nothing wrong in substitution but the problem is on the ban of wheat .Let the common man in these country decide what he likes to eat .

Warburtons Enters Indian Naan Bread Segment

With presence of large population from South Asian countries impact of which can be found on native popualtion's food habits in that country , as recently chicken curry has been declared as second most loved food in UK. Curry Mania ---. Naan are popular bread for people from India , Pakistan , Afghanistan and Bangladesh .

|

| source : warburtons.co.uk |

|

| courtesy :thegrocer.co.uk |

Warburtons naan are packed in square wrapping and could be used as rolls or with several delicious toppings .

.

Warburtons naan bread are sold in two flavours - plain & garlic . It would be interesting to see whether naan breads would be as popular as Indian chicken curry .

Subscribe to:

Posts (Atom)

Contact Us - bakerybazar@gmail.com

" Learn all about bakery processes,bakery equipments and machinery,packaging , bakery ingredients and food safety.Each brand of bakery product has its own storyand history behind them to tell .Bakerybazar intends to discover and unravel these stories before you".You can submit for freePress Release,Product Launches ,New Technologies, Company Presentation, New Markets and Distribution Related News, Trade Show ,News Trade Mission Participation, Mergers and Aquisitions ,Financial Reports ,Product Sourcing Activities ,New Hires and other HR news--- any thing related to bakery industry. Write to bakerybazar@gmail.com